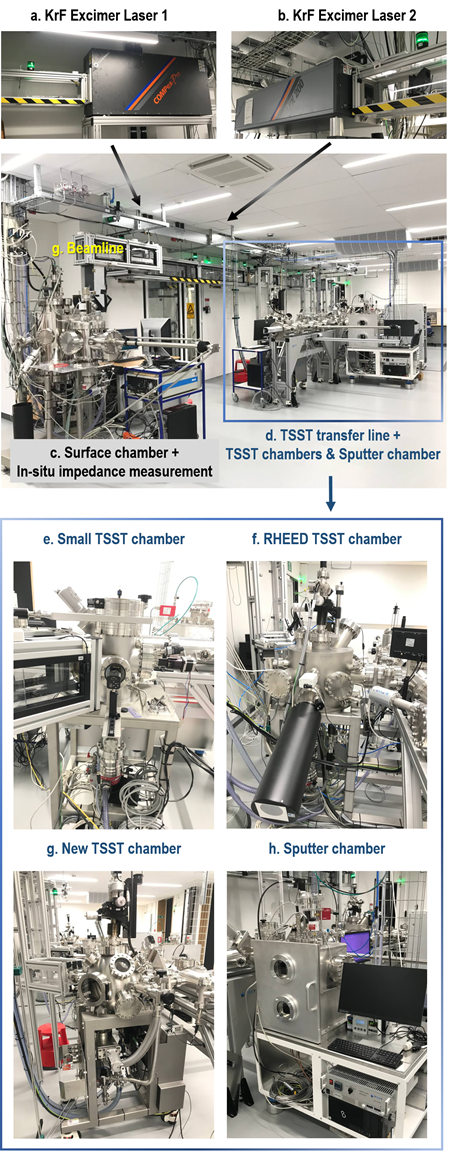

The group has a state-of-the-art Pulsed Laser Deposition (PLD) cluster system, which includes two KrF excimer lasers (a and b), five chambers (c, e, f, g, and h), transfer line (d), and a beamline system (g). As shown in the figure, the beamline system with a smart safety interlock enables the distribution of laser beams simultaneously to different chambers through the closed lane. So that the PLD cluster system can be used in an efficient way.

Ultra-high vacuum (UHV) Surface chamber (c) allows the large area (1~2 inches) deposition of high-quality thin layer and also the multilayers using a multi-target carousel. The deposition conditions vary over a wide range of substrate temperatures (RT to 800 °C) and oxygen/nitrogen pressures (10-8 - 10 mbar). Additionally, it is capable of in-situ diagnostics of impedance spectroscopy to explore the ionic conductivity of the films during the deposition.

TSST transfer line (d) connects three TSST chambers (e, f, and g) and Sputter chamber (h) for the deposition of the metal layer with good metallic contacts by transferring samples in UHV conditions. The samples can be loaded and transferred through a load-lock chamber. Lastly, Reflective High Energy Electron Diffraction (RHEED) TSST chamber (f) provides in-situ monitoring of the growth process to determine the growth mechanism (layer-by-layer, step flow, or 3D island growth) and the number of atomic layers.

Click here to open figure

Location: B310, Room 920

Responsible: Dennis Valbjørn Christensen, Shinhee Yun